3D computer-aided design (CAD) has revolutionised the way mechanical design is carried out. Bentech is at the forefront of this technology, tying together our CAD design, 3D printing and laser cutting services for rapid prototyping and cost effective solutions for our customers.

3D CAD software helps to create detailed and realistic models. Bentech has a current license for the latest version of Solidworks 3D CAD to ensure we can produce the best possible designs.

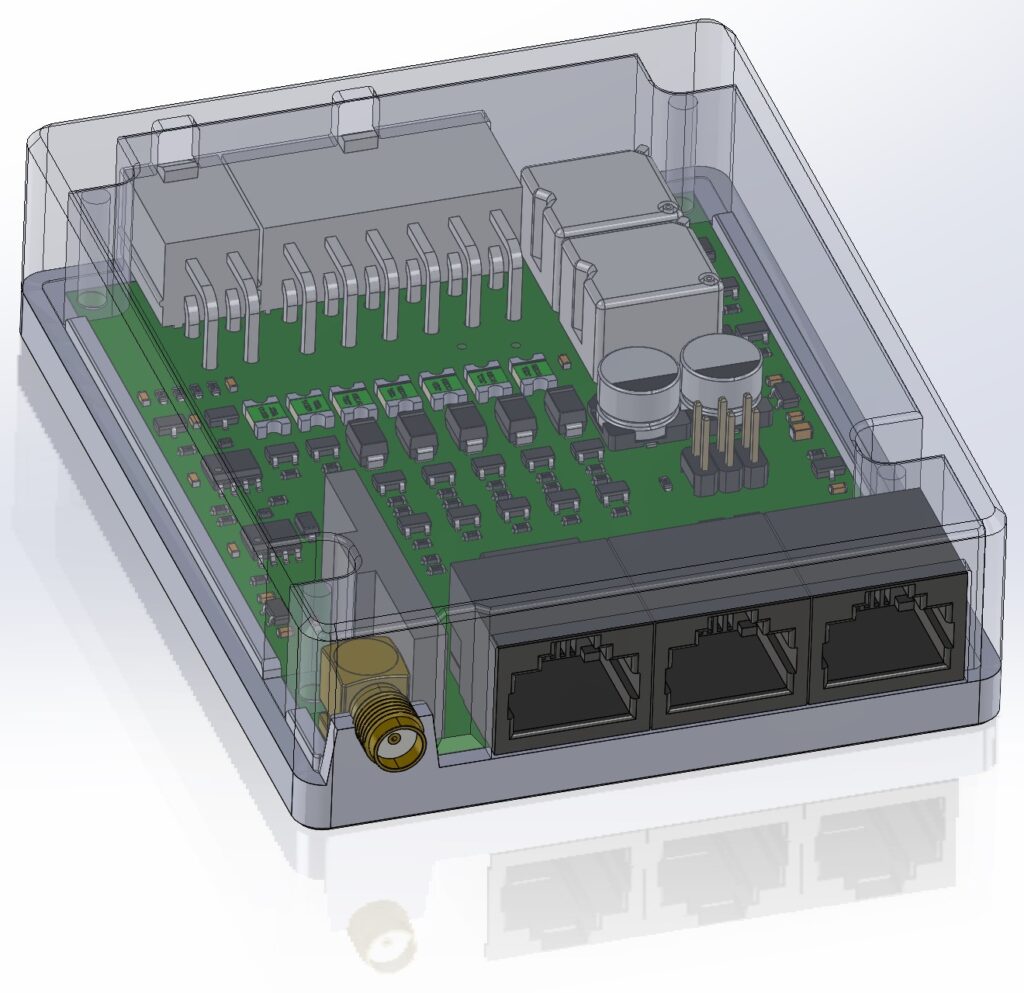

Using this software, we can create virtual prototypes that provide an accurate representation of the final product or system, even at the prototyping phase.

Combined with our 3D printing capabilities, this enables us to test different scenarios and make changes before any production takes place. As a result, costly errors can be avoided, saving both time and money in the long run.

Bentech is able to assist with 3D Mechanical Design including the creation and development of mechanical systems and devices.

Our skilled team can create, modify, analyse, and optimise designs in a virtual environment.

With the help of 3D CAD software, we can create detailed models with accurate dimensions and tolerances while simulating real-world conditions. This allows for better visualisation of the final product before it is manufactured which helps to identify potential issues early on in the process.

Use of 3D CAD can improve efficiency, reduce errors, and accelerate product development cycles.

Failing to leave sufficient space for electronic components within a product’s mechanical design is a common issue. When problems are discovered at the end of the project, it can lead to significant re-design costs. We prefer to get involved in mechanical design at an earlier stage to ensure the electronic solution will fit well and be relevant to the componentry available.

The sooner you involve an electronic design company like Bentech in your product, the more effort, time and money you can save. Previously we have had to advise companies that the electronic sub-assembly cannot fit into an otherwise perfect product design. Contact us today to avoid this happening to you!

Our engineers can start working once you send us the files. Even if you only have hand-drawn sketches, we can draw up your model for you with our CAD design service.

That will be the very first step of visualising your idea and understanding how it can work.

In addition to our 3D printing service that works well for prototyping and small volume production, we are also able to arrange injection molding a production component. This may be more suitable for higher volumes, or for parts with more critical requirements.

Injection molding means a specialised tool is fabricated and the molten material (typically ABS plastic) is injected into a cavity and cooled to form the part.

It offers high reliability, consistency and a better finish for a lower unit cost. While there is an upfront investment in tooling the mold, it makes sense for high volume production runs.

The team at Bentech have extensive knowledge in designing parts for injection molding. We can start with a 3D printed design for prototyping purposes, then work with our industry partners to have the tool designed and fabricated and arrange for your parts to be produced, typically as a component in our manufacturing process for your end product.

As we have been involved in the design and development of the SYP Automatic Fluid Sampler since its very beginning, our 3D CAD capabilities were well utilised.

Being tasked with both electronic and mechanical design elements of the project allowed us to ensure components were designed to fit perfectly right from the start.

From concept to final product, multiple prototype revisions were designed and 3D printed entirely in-house at Bentech. Even once production started, we were able to make tweaks to the design to improve the assembly process and have revised components printed within hours!

© 2024 Bentech Limited • All Rights Reserved