When it comes to manufacturing products with electronic components, quality control is an essential part of the process.

Bentech has the equipment and expertise to conduct complete quality control and testing for performance and reliability during product development and prototyping. We also follow this up by conducting complete unit testing during the manufacturing process.

We believe that quality control, including prototyping and testing, is key to successful product development. It’s best to identify challenges prior to stepping out to the market.

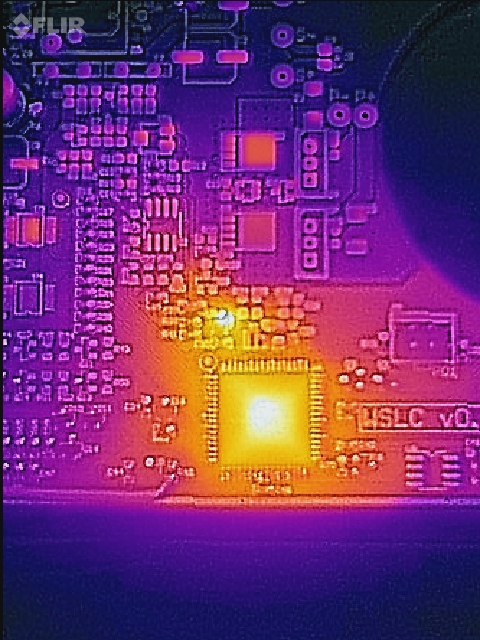

We will make certain that your new product design is properly tested including environmental usability and other stress testing so that your product can operate in the environment it’s created for.

We test each product that we manufacture to ensure consistent quality your customers will appreciate.

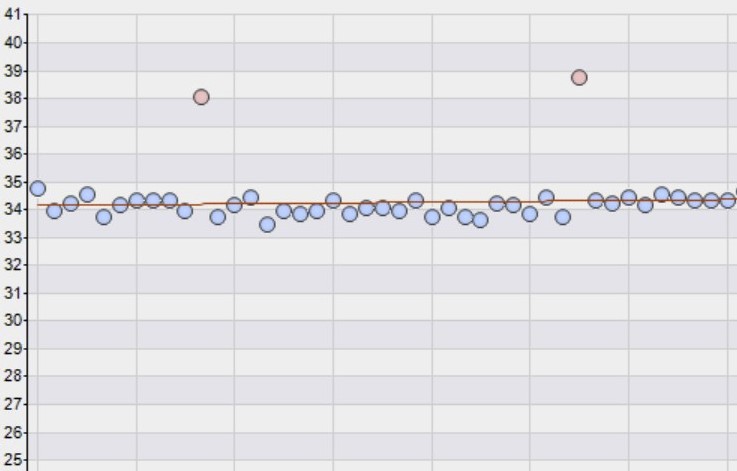

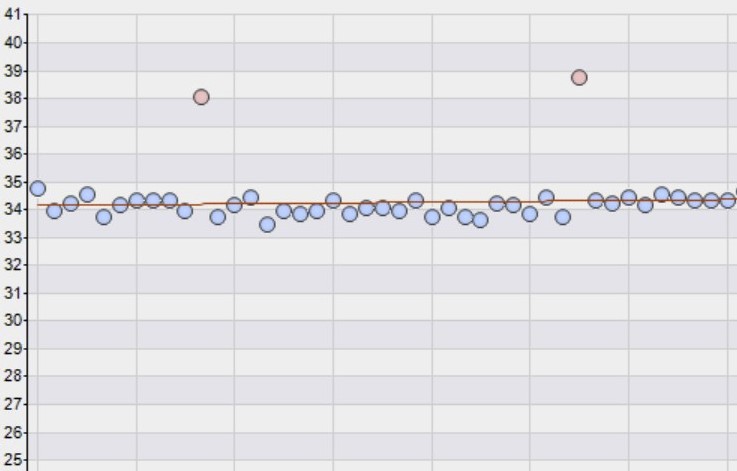

This is a real example of testing. Each dot represents the value of one parameter for each unit tested. As you can see, most are pretty consistent and it’s clear which ones are out of range and therefore have to be investigated and repaired.

We believe in delivering a quality product, so we have invested heavily in developing our own bespoke production management and testing solution.

When your product is manufactured by Bentech, an automated test is written specifically for the product. All functional aspects of the unit are measured and all parameters must be within acceptable limits for the unit to proceed.

A performance report is saved in a database and a complete record of the unit is kept for the life of the project.

Parameter variations can be analysed so improvements can be made to the design and changes between batches can be identified and investigated as necessary. This allows most issues to be identified before the product is dispatched and they become problem in the field.

When it comes to turning an idea into a tangible product ready for the market, creating a prototype is the most efficient approach.

Even with just one prototype, you can assess the functionality of your product and persuade potential investors that it is a valuable investment. When prototyping is done within New Zealand by professionals like Bentech, there is no time wasted on shipping and you can have multiple prototypes created if required.

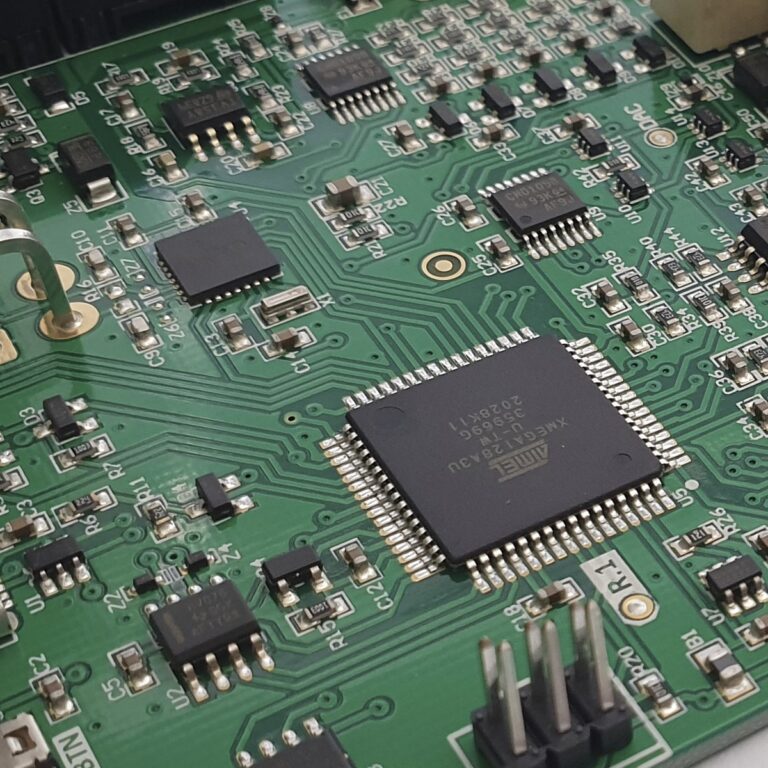

Bentech’s team of experts is capable of creating a circuit board prototype using components we can supply consistently. Whether it is building a proof of concept or a fully working prototype, you can be sure that we will put it through its paces.

We have your final product and potential future development in mind at every step of the process, so that you get maximum benefit while working with Bentech.

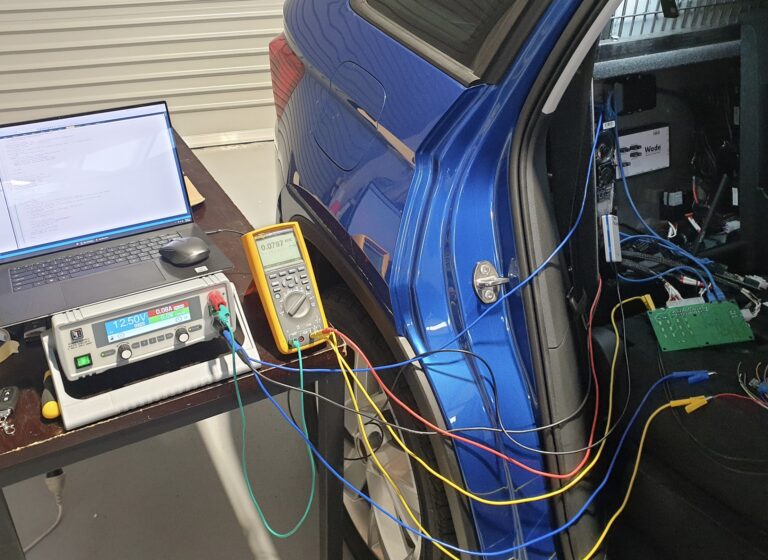

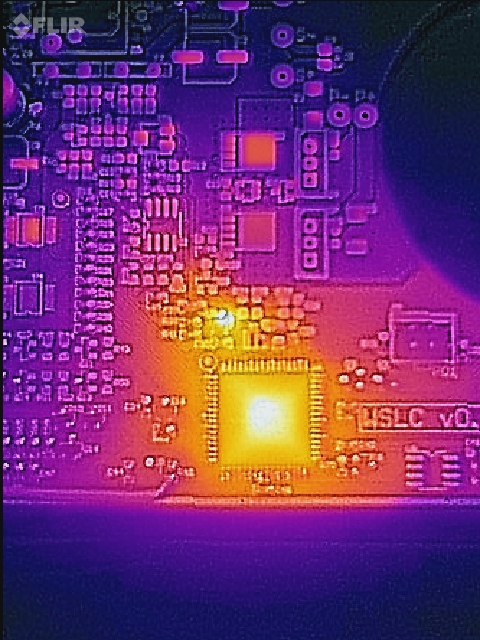

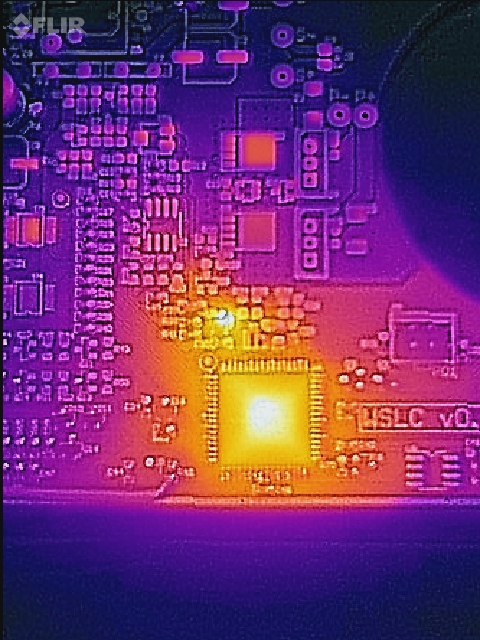

We understand that testing is a critical part of ensuring the product is reliable, safe, and compliant. That’s why we have invested in a modern testing facility, Bentech Lab, where we offer a wide range of testing capabilities for electronic products and designs.

Our experienced engineers are highly proficient in PCB fault finding and software debugging. We can quickly identify and resolve any issues during the testing phase. This not only results in a faster development process, but also ensures that your product is more reliable and meets the highest standards of quality.

Bentech has equipment and expertise to test and identify challenges during product development. We can build and test prototype within short timeframe that supports your product development timeline.

Our aim is to help you ensure that the product is reliable, safe, and compliant so that you can bring it to market with confidence.

Bentech engineers are proficient at identifying and resolving issues quickly and efficiently, which results in a faster development process and a more reliable product.

Those who used to get prototypes done overseas know how much faster product development process occur when prototypes are done locally in NZ.

Often times Bentech gets involved in product development at a later stage when electronic design is completed but there is a need to confirm viability of the product in real live conditions. That is when various stress-testing allows us to assist product developers to gain reassurance in the quality of their product. That includes:

Our testing equipment and techniques are up-to-date, we use the latest industry-standard tools to ensure accurate and reliable results.

While Quality Control is the last step in the Manufacturing process, we think it’s one of the most important.

That is why we developed a Bespoke Approach that allows us to be able to test each item we manufacture for a wide range of parameters to ensure consistent performance of each.

That gives our clients the reassurance that every item is compliant with necessary regulations, is able to operate in the environment it’s designed for, and is fit for purpose.

Bentech has the capacity to manufacture smaller runs in-house and has established New Zealand-based partners to produce greater volume when required. That is why we can help with any volume required for your project, including volume based.

© 2024 Bentech Limited • All Rights Reserved